| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : YDL

Model Number : YDLFV

Certification : ISO , CE

Place of Origin : China

MOQ : 1 Set

Price : Negotiation

Payment Terms : L/C, T/T

Supply Ability : 200 Sets / Month

Delivery Time : Within 30-60 days

Packaging Details : With plastic foam firstly and then outside by wooden cases(standard export packaging) for beer fermenting machine

Material : Stainless Steel 304 / 316

Thickness : 2.00 mm - 3.00 mm

Color : Mirror SUS

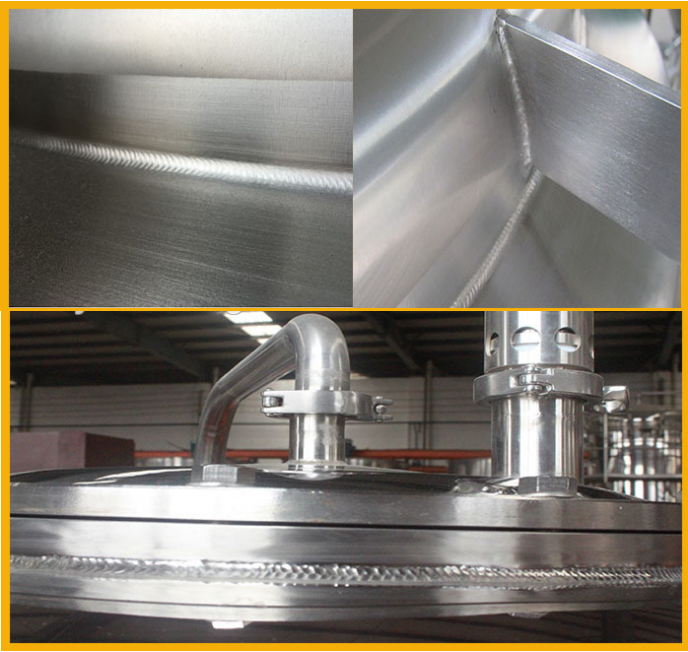

Welding : 100% TIG

Voltage : Customer request

Insulation : 50mm / 100mm

50mm Polyurethane Insulation Conical Beer FermenterWith 100% TIG Welding

Products Specifications

Fermenting is the process during which the yeast transforms the wort into beer.Lagerings takes place after fermenting and is the time given to the beer to stabilize and age after fermenting.

Our Conical Beer Fermenter capacity available from 1 Barrel to 100 Barrels with an average 25% Head Space. All tank have a Dish top , Cylinder body & 60 /70° Cone Bottom . Certified stainless steel material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

Dimple Plate jacket forGlycol cooling & high efficient Polyurethane foam insulated. All tanks use Tri-clamp connections and designed for up to 14.7 PSI and tested at 30 PSI. We can custom fabricate any tank to meetyour brewery’s space and height restrictions.

Standard Features

• Dual zone dimple cooling jackets (3 or more on larger tanks)

• Interior shell: 304 stainless steel, thickness 3mm /11 gauge

• Cooling jacket: 304 stainless steel, thickness 2mm /14 gauge

• Exterior shell: 304 stainless steel, thickness 2mm /14 gauge

• 2” Polyurethane insulation

• Interior surface to finish pickled and passivated

• Exterior surface to brushed, #4 finish

• 580x480mm Side manway, shadowless

• Dry hop inlet at top;

• Accessories:

Sample Valve x1;

Pressure relief/vacuum valve x1;

Temp. sensor / thermometer x1;

Rotating racking arm with butterfly valve x1;

Bottom outlet with butterfly valve x1;

Spraying Ball with down tube x1;

Stainless pipe legs with adjustable footpads x4;

Dimension and Capacity Paremeters (FYI)

| Capacity | Cylinder(ODxH) | OAH | Inner Thickness |

| 7BBL | 1000 x 1250mm | 2530mm | 3mm |

| 10BBL | 1150 x 1250mm | 2670mm | 3mm |

| 15BBL | 1250 x 1680mm | 3250mm | 3mm |

| 20BBL | 1400 x 1700mm | 3400mm | 3mm |

| 30BBL | 1650 x 1850mm | 3740mm | 3mm |

| 40BBL | 1750 x 2050mm | 4040mm | 3mm |

| 50BBL | 1750 x 2750mm | 4770mm | 3mm |

| 60BBL | 1150 x 1250mm | 2670mm | 3mm |

| 80BBL | 2100 x 2900mm | 5300mm | 3mm |

| 100BBL | 2200 x 3350mm | 5850mm | 3mm |

| Model & Specification | 100L | 200L | 500L | 1000L | 2000L | 5000L | 10000L | 20000L | 50000L |

| Diameter(mm) | 400 | 500 | 700 | 900 | 1200 | 1500 | 1800 | 2300 | 3100 |

| Height(mm) | 2000 | 2300 | 2650 | 2900 | 3800 | 4480 | 5250 | 6550 | 8550 |

| Pressure inside tank (Mpa) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Pressure inside jacket (Mpa) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | pipe0.3 | pipe0.3 | pipe0.3 |

| Impeller number | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 4 |

| Mixing speed (r/min) | 400 | 360 | 265 | 220 | 180 | 160 | 145 | 125 | 110 |

| Rotor power (r/min) | 0.55 | 0.75 | 1.5 | 2.2 | 4 | 7.5 | 17 | 30 | 55 |

| Cooling type | jacket | tube | |||||||

Production Process

|

|

100% TIG Welding Conical Beer Fermenter With 50MM Polyurethane Insulation Images |